| Viktoras Grigaliūnas, Šarūnas Meškinis, Dalius Jucius, Algirdas Lazauskas, Mindaugas Andrulevičius, Asta Guobienė, Brigita Abakevičienė, Mindaugas Juodėnas, Rimantas Gudaitis, Vitoldas Kopustinskas, Andrius Vasiliauskas, Albinas Kasparaitis. Anti-fogging technique for protection of optical grating scales (2023). Optical Materials. |

|

|

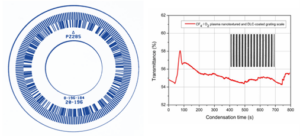

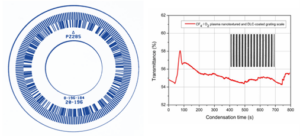

The combined technique consisting of CF4/O2 plasma nanotexturing of the glass surface and the deposition of the SiOx containing DLC film on the top of the grating scale followed by O2 plasma treatment was designed for the long-lasting protection of the optical grating scales from fogging. XPS analysis of the DLC film before and after O2 plasma treatment shows that even short exposure to O2 plasma produces oxidized silicon on the surface of the DLC film. O2 plasma treatment time of 180 s leads to the increase of the carbon C=C peak (sp2 hybridization) intensity from 15% to 32%, and a decrease of the carbon C-C peak (sp3 hybridization) intensity from 67% to 45%. The wetting angle of the plasma nanotextured and DLC-coated optical grating scale retains superhydrophilic properties and optical transmittance after long-term storage. The proposed technique ensures long-lasting operation of the encoder with the optical grating scale below dew point temperature.

|

| Nadzeya Khinevich, Domantas Peckus, Asta Tamulevičienė, Gerda Klimaitė, Joel Henzie, Tomas Tamulevičius, Sigitas Tamulevičius. Size and crystallinity effect on the ultrafast optical response of chemically synthesized silver nanoparticles (2023). Journal of Materiomics |

|

|

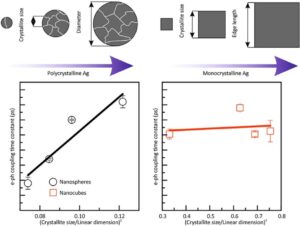

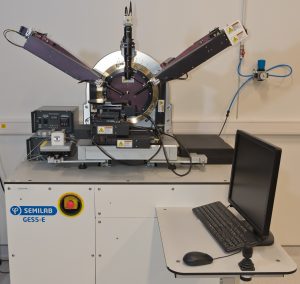

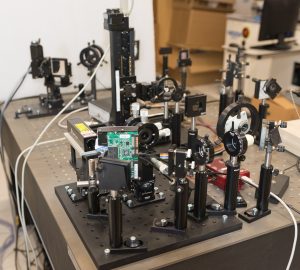

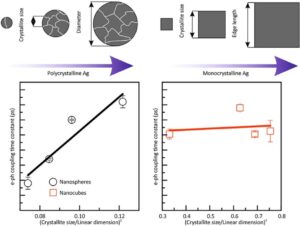

TThis article shows how a transient absorption spectrometer (TAS) can be useful for determining the crystallinity of silver nanoparticles. Silver nanoparticles are interesting because of their plasmonic properties. Localized surface plasmon resonance is known to relax by several processes, such as electron-electron scattering, electron-phonon (e-ph) coupling, and phonon-phonon scattering. Of these processes, the e-ph coupling is the most interesting, as it allows determining where nanoparticles are best used, for example, for photocatalysis (long e-ph coupling) or thermal effects (short e-ph couplin. To determine how the crystalline structure affects the e-ph coupling durations, two types of samples were studied: monocrystalline silver nanocubes and polycrystalline (increasing polycrystallinity with increasing size) silver nanospheres, the sizes of which were in the length range of 30-60 nm. It was found that in monocrystalline nanocubes, the duration of e-ph coupling did not depend on the size of the edge of the cube, while in polycrystalline spheres, the duration of e-ph coupling decreased linearly with increasing diameter. Finally, we have demonstrated that the e-ph coupling decay time constant depends linearly on (Crystallite size / linear dimension of Ag NPs)2 for polycrystalline Ag nanospheres, while monocrystalline Ag nanocubes do not show any clear dependence on this ratio. This fact illustrates that the e-ph coupling time could be used to evaluate crystallinity and crystallite size in plasmonic metal nanoparticles when the size (surface area) of the nanoparticle is known.

|

| Domantas Peckus, Asta Tamulevičienė, Karine Mougin, Arnaud Spangenberg, Loic Vidal, Quentin Bauerlin, Marc Keller, Joel Henzie, Linas Puodžiukynas, Tomas Tamulevičius, Sigitas Tamulevičius. Shape influence on the ultrafast plasmonic properties of gold nanoparticles (2022). Optics Express. |

|

|

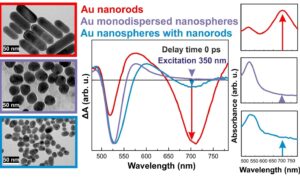

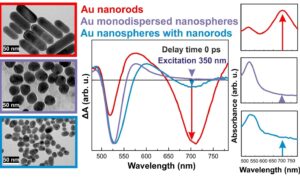

The article shows how ultrafast differential absorption spectroscopy (TAS) can be used to study the sizes, shapes, and homogeneity of plasmonic gold nanoparticles. Scanning electron microscopy or transmission electron microscopy can usually be used quite reliably for these studies, but these measurements are relatively slow, the equipment used is expensive, and the studies involve relatively small amounts of nanoparticles. Typically, measurements of ultraviolet–visible light (UV–VIS) steady-state absorption spectra are used for rapid studies of plasmonic metal nanoparticles. The analysis is simple and fast, and measurement equipment is widely available, so this type of study is very common, but it is difficult for this method to reliably distinguish different forms of nanoparticles. During our research, we found that the dynamic TAS method can help determine the size, shape, or another form of nanoparticle impurities much more reliably and accurately than measurements of steady-state UV-VIS absorption spectra. These results can be useful for studying the properties of plasmonic metal nanoparticles and are of great significance for materials science. This article has been awarded the Editor’s Choice recognition, which is only given to the articles that are significant in their field and have excellent scientific quality.

|

| Agnė Šulčiūtė, Keita Nishimura, Evgeniia Gilshtein, Federico Cesano, Guido Viscardi, Albert G. Nasibulin, Yutaka Ohno, Simas Račkauskas. ZnO Nanostructures Application in Electrochemistry: Influence of Morphology (2021). The Journal of Physical Chemistry C. |

|

|

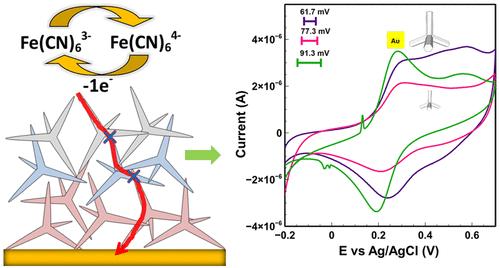

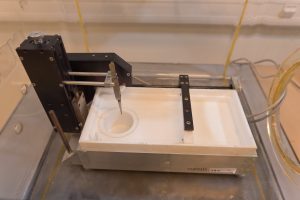

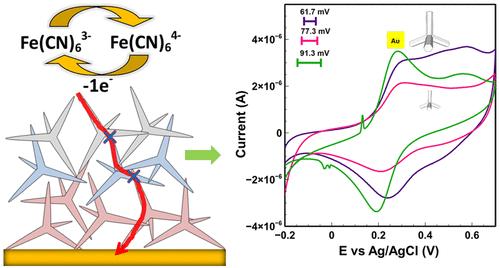

In this work we analyze how a form of zinc oxide (ZnO) nanomaterials determines their electrochemical properties. Different forms of ZnO were compared: tetrapods, nanoparticles and nanowires. ZnO tetrapods synthesized in our laboratory were found to have better electrochemical properties than commercial ZnO (nanoparticles, nanowires). ZnO tetrapods have the highest active surface area (A = A= 0.095 cm2), and the lowest number of electronic transport skaičiaus (DEp = 61.7 mV), which is very close to the theoretical value. This detailed study of the influence of ZnO nanostructure and form on electrochemical properties, will be useful in the development of future biosensors.

|

| Mindaugas Juodėnas, Domantas Peckus, Tomas Tamulevičius, Yusuke Yamauchi, Sigitas Tamulevičius, and Joel Henzie, Effect of Ag Nanocube Optomechanical Modes on Plasmonic Surface Lattice Resonances (2020). ACS Photonics |

|

|

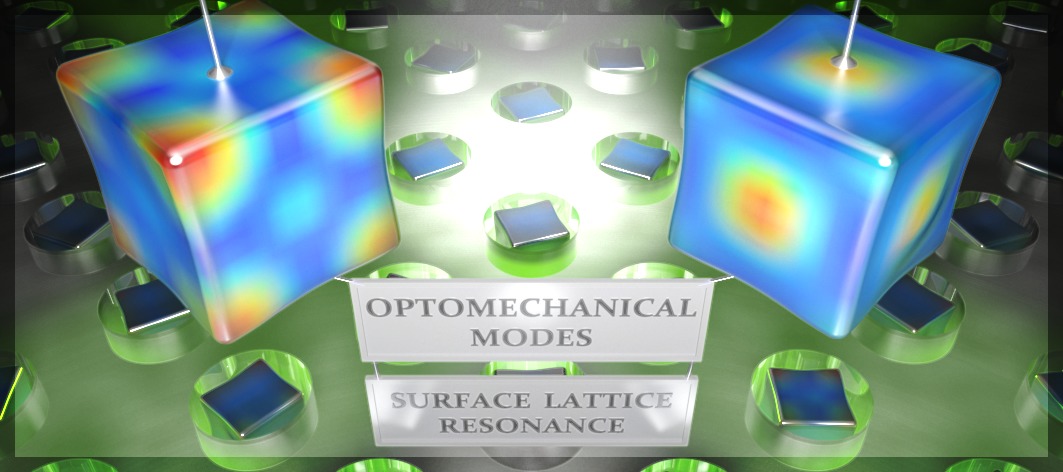

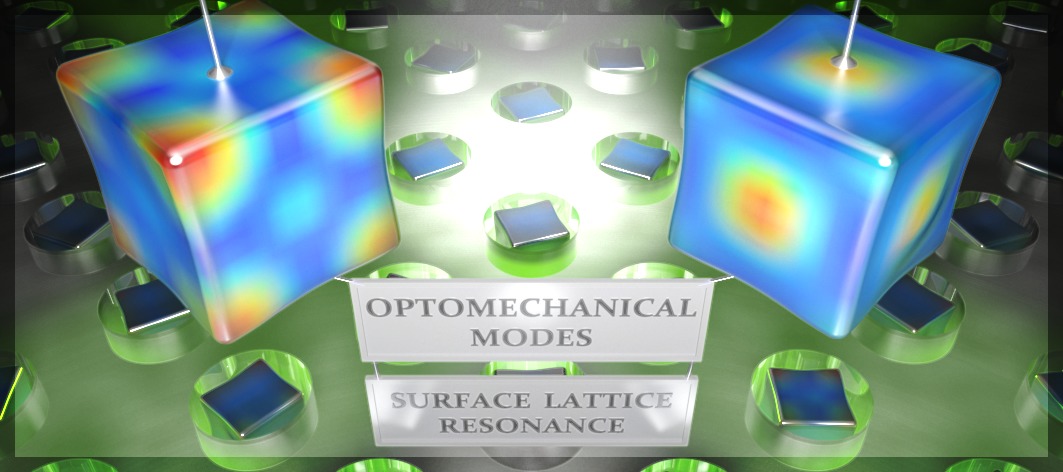

This article describes the interaction of ultrafast light pulses with silver nanoparticles and their arrays. We showed that light pulses elapsing a trillionth of a second (1/1 000 000 000 000 s) can excite mechanical vibrations in nanoparticles that are a thousand times smaller than the width of a human hair. These processes can be visualized in dynamic light absorption spectra because the color of plasmonic materials depends on their size and shape which can be modulated by mechanical vibrations. We investigated arrays of such nanoparticles and described the influence of local ultrafast oscillations on a long-range phenomenon—the surface lattice resonance (a collective optical response of regular nanoparticle arrays), which is extremely sensitive to the color of light scattered by the nanoparticles. Our observations will allow to create ultrafast elements of nanophotonics and opens the doors for a new generation of nanolasers.

|

| Domantas Peckus, Šarūnas Meškinis, Andrius Vasiliauskas, Erika Rajackaitė, Mindaugas Andrulevičius, Vitoldas Kopustinskas, Sigitas Tamulevičius, Structure and optical properties of diamond like carbon films containing aluminium and alumina (2020) Applied Surface Science |

|

|

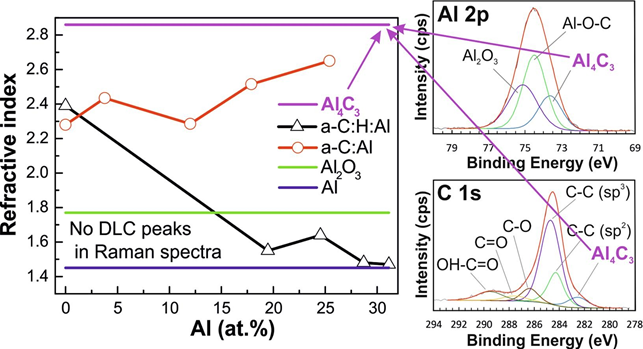

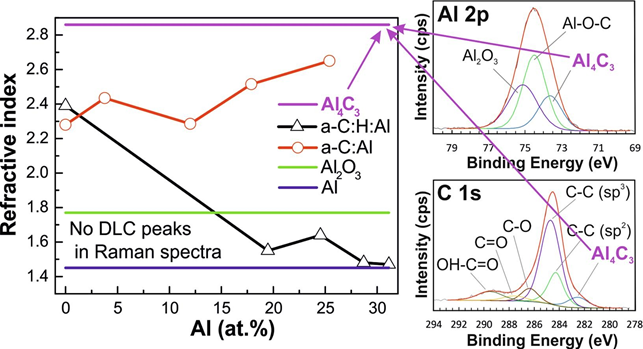

This paper describes the results of studies of diamond-like carbon coatings (coatings containing carbon atoms of different spatial configurations – typical for crystalline diamond and graphite) with different concentrations of aluminum nanoparticles (DLC:Al). We investigated two different types of magnetron sputtering deposited DLC coatings: hydrogenated (coatings also contain hydrogen atoms) and non-hydrogenated with different Al atomic concentrations in them. If the studies of the composition of hydrogenated DLC:Al did not show unexpected results – alumina (AlOx) derivatives were formed in these coatings, then in addition to AlOx compounds, aluminum carbide (AlCx) derivatives were formed in non-hydrogenated DLC:Al. It is known that the formation of AlCx is usually very inefficient and requires temperatures above 1000 oC, therefore most often during synthesis, which takes place at much lower temperatures (e.g. room temperature), no AlCx is formed in DLC:Al films. The fact that we were able to obtain AlCx at relatively very low room temperatures is an interesting result, and the better understanding of the synthesis method we used may contribute to the efficient preparation of AlCx coatings in the future. Thanks to their high thermal conductivity, low thermal expansion and high refractive index, these coatings can be widely applied in optoelectronics. The sufficiently simple magnetron-based coating preparation method described in the article may contribute to the wide practical applications of AlCx in the future.

|

| Algirdas Lazauskas, Liutauras Marcinauskas, Mindaugas Andrulevičius, Modification of Graphene Oxide/V2O5• n H2O Nanocomposite Films via Direct Laser Irradiation (2020). ACS Applied Materials & Interfaces |

|

|

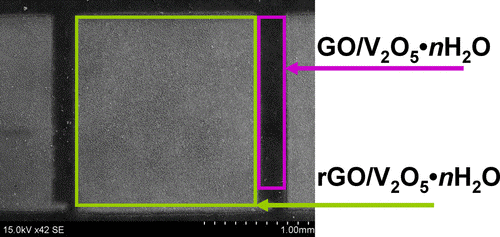

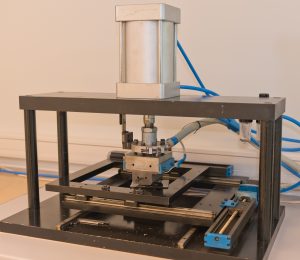

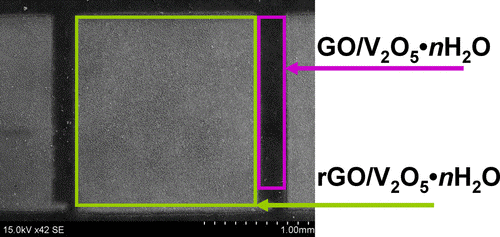

Herein, photothermal modification of nanocomposite films consisting of hydrated vanadium pentoxide (V2O5·nH2O) nanoribbons wrapped with graphene oxide (GO) flakes was performed via 405 nm direct laser irradiation. The combination of X-ray diffraction, X-ray photoelectron spectroscopy, Raman scattering, transmission electron microscopy, and scanning electron microscopy allowed comprehensive characterization of physical and chemical changes of GO/V2O5·nH2O nanocomposite films upon photothermal modification. The modified nanocomposite films exhibited porous surface morphology (17.27 m2 g–1) consisting of randomly distributed pillarlike protrusions. The photothermal modification process of GO/V2O5·nH2O enhanced the electrical conductivity of nanocomposite from 1.6 to 6.8 S/m. It was also determined that the direct laser irradiation of GO/V2O5·nH2O resulted in considerable decrease of C–O bounds as well as O–H functional groups with an increase of the laser power density.

|

| Algirdas Lazauskas, Dalius Jucius, Valentinas Baltrušaitis, Rimantas Gudaitis, Igoris Prosyčevas, Brigita Abakevičienė, Asta Guobienė, Mindaugas Andrulevičius, Viktoras Grigaliūnas, Shape-Memory Asisted Scratch-Healing of Transparent Thiol-Ene Coatings (2019). Materials |

|

|

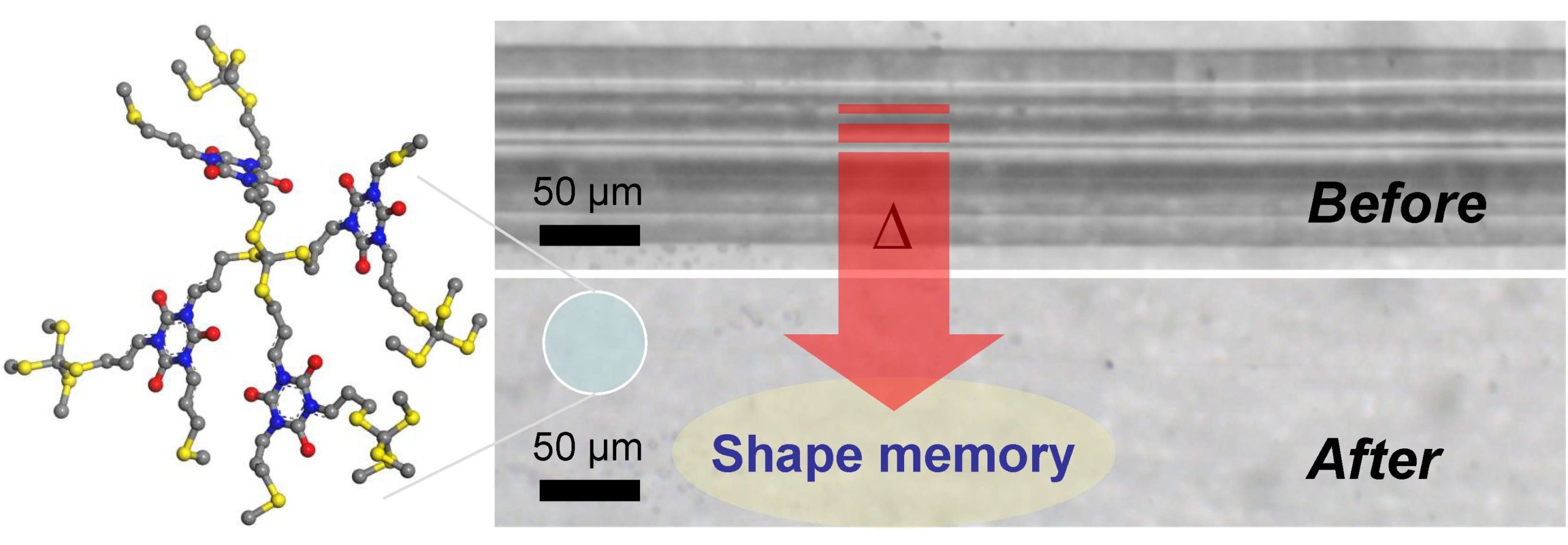

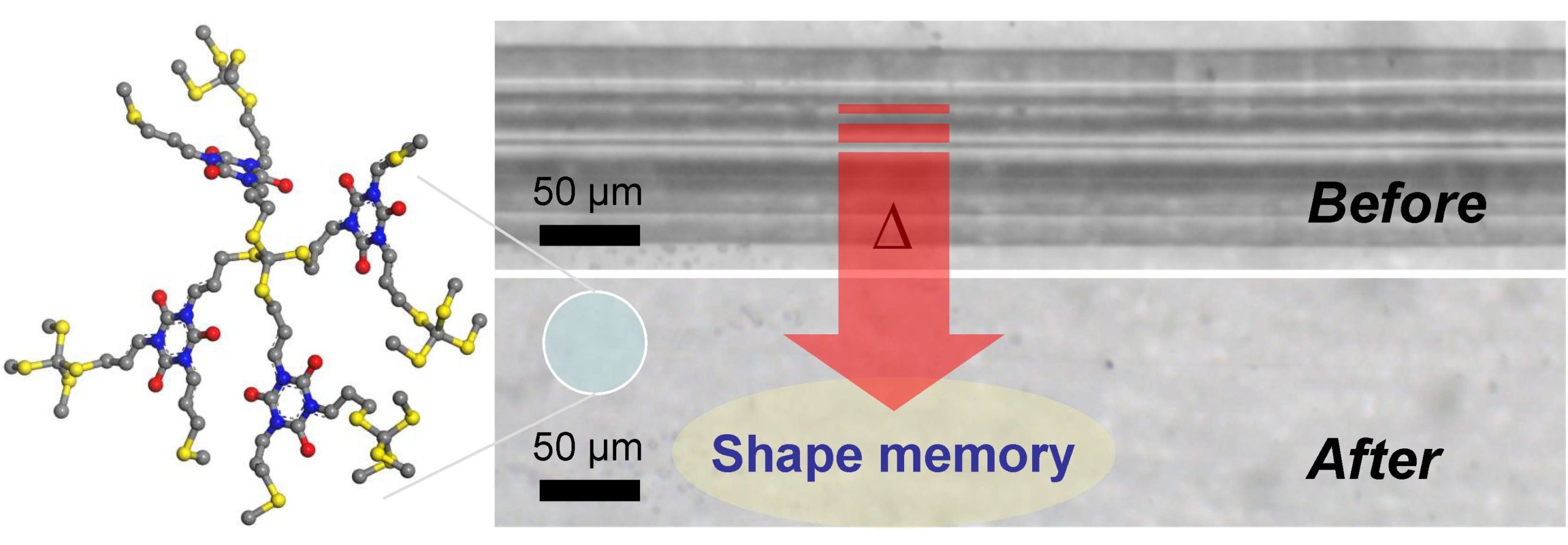

This paper reports on the properties of scratch-healing thiol-ene coatings synthesized at the Institute of Materials Science at Kaunas University of Technology on the basis of photopolymerizable composition prepared as a mixture of pentaerythritol tetrakis(3-mercaptopropionate) (PETMP) and 1,3,5-triallyl-1,3,5-triazine-2,4,6(1H,3H,5H)-trione (TTT), with 1 wt. % of 2,2-dimethoxy-2-phenylacetophenone (DMPA) photoinitiator. It was demonstrated that such coatings exhibit high optical transparency, elasticity and shape-memory. The crosslinked PETMP-TTT polymer network was capable to initiate scratch recovery not only under the influence of an external stimulus but also at the room conditions. It was suggested that such coatings could be integrated in a new generation of the optoelectronic products.

|

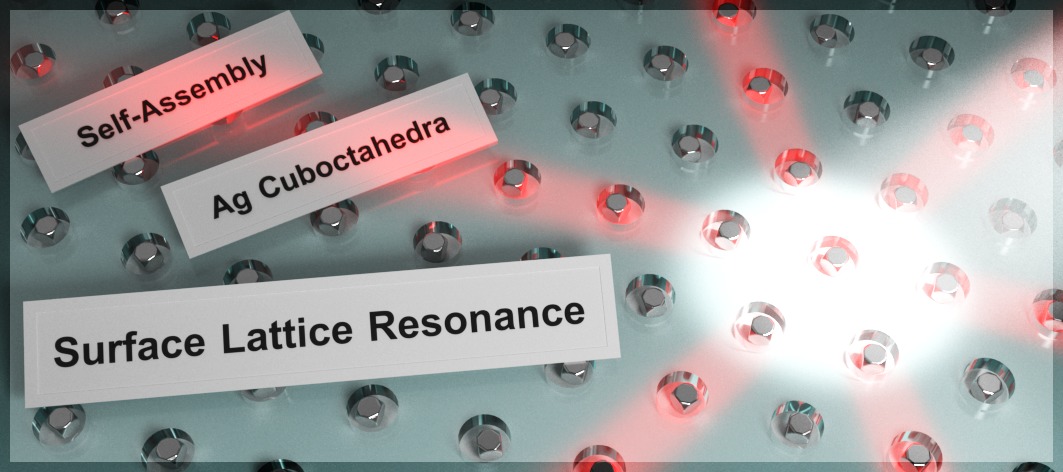

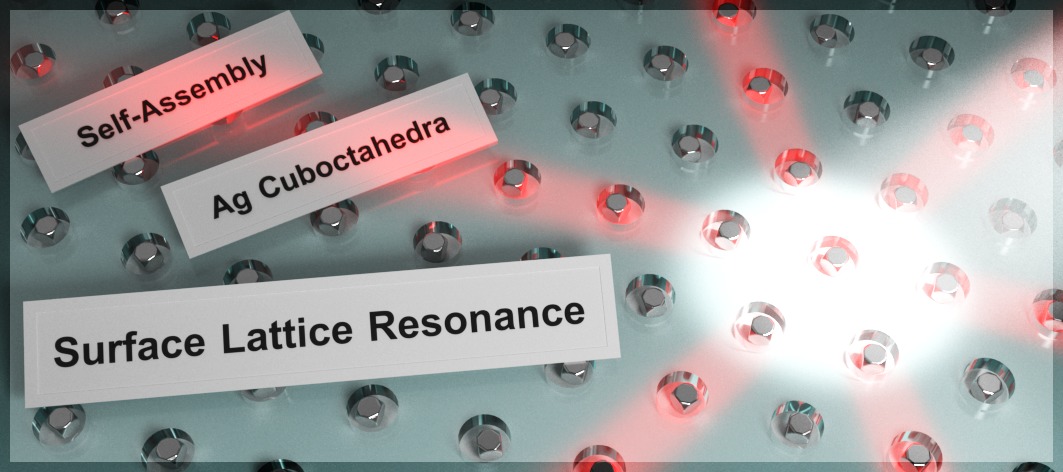

| Mindaugas Juodėnas, Tomas Tamulevičius, Joel Henzie, Donats Erts, and Sigitas Tamulevičius, Surface Lattice Resonances in Self-Assembled Arrays of Monodisperse Ag Cuboctahedra (2019). ACS Nano |

|

|

This article describes a new optical phenomenon—a surface lattice resonance (a collective optical response of regular nanoparticle arrays) and a method to produce the required plasmonic nanostructures using capillary force-assisted nanoparticle assembly. We showed that this extremely wavelength-sensitive phenomenon can be generated by arranging noble metal (gold, silver) nanoparticles on specifically patterned templates. Our method avoids serial writing of individual nanoparticles by using self-assembly to arrange them en masse from a colloidal solution. These surface lattice resonance-featuring nanostructures allow to manipulate light and enhance the electric field both locally and throughout the plane of the array, which is essential for extra-sensitive biosensors and nanolasers.

|