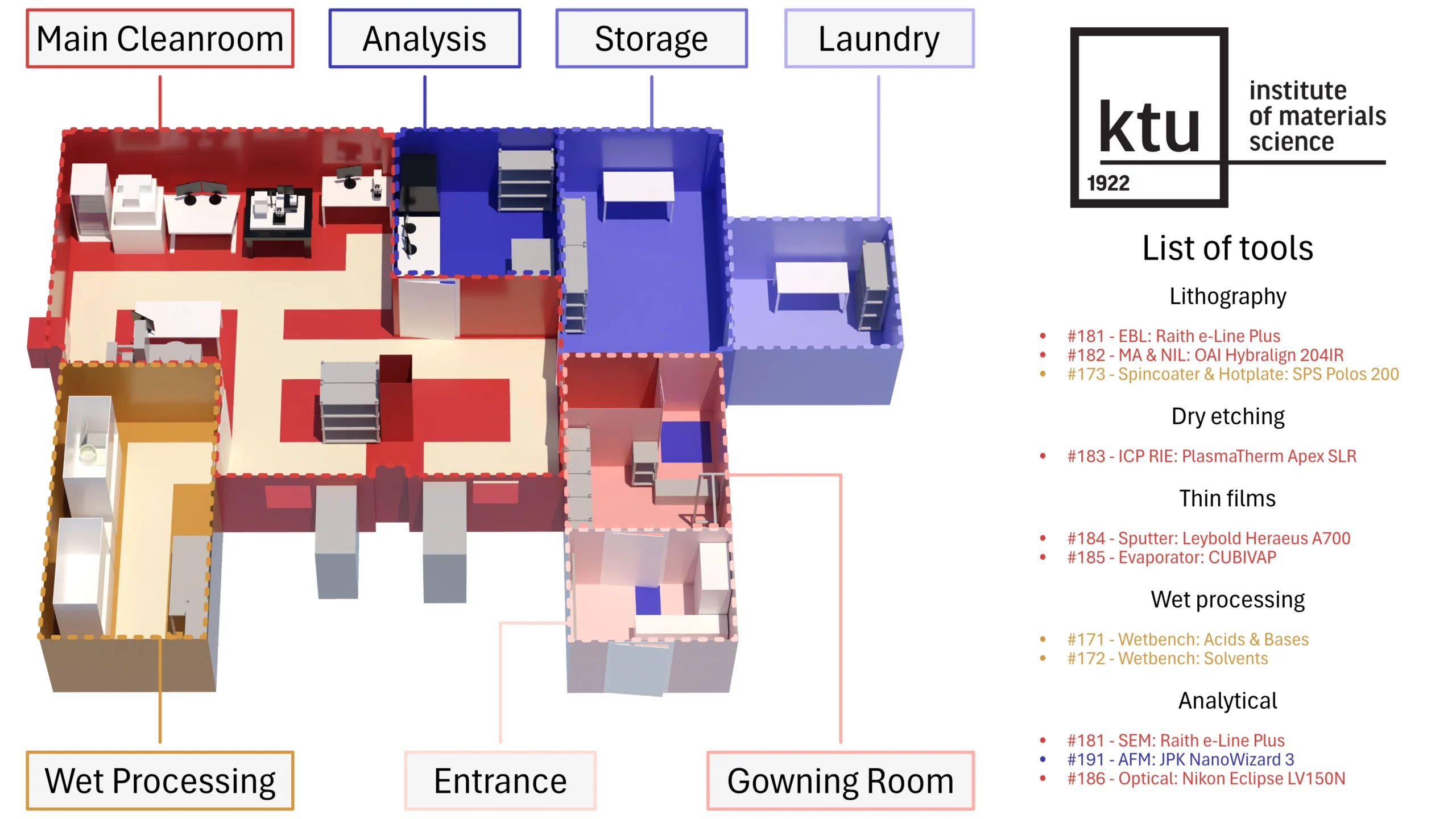

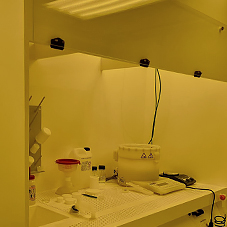

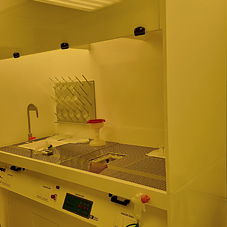

MMI Cleanroom is a hub of nanofabrication in a controlled environment at Kaunas University of Technology and is managed by the Institute of Materials Science. Established in 2014, the 130 m² ISO5 (Class 100) cleanroom facility is open to the entire university community, as well as external academic and commercial partners.

Since 2019, MMI Cleanroom is part of the EuroNanoLab network, which is a distributed research infrastructure uniting 44 cleanrooms in 14 countries. It provides academic and industrial access to world-class nanofabrication services and expertise for exploratory research (low-TRL). EuroNanoLab nodes welcome any external users in an open-access mode.